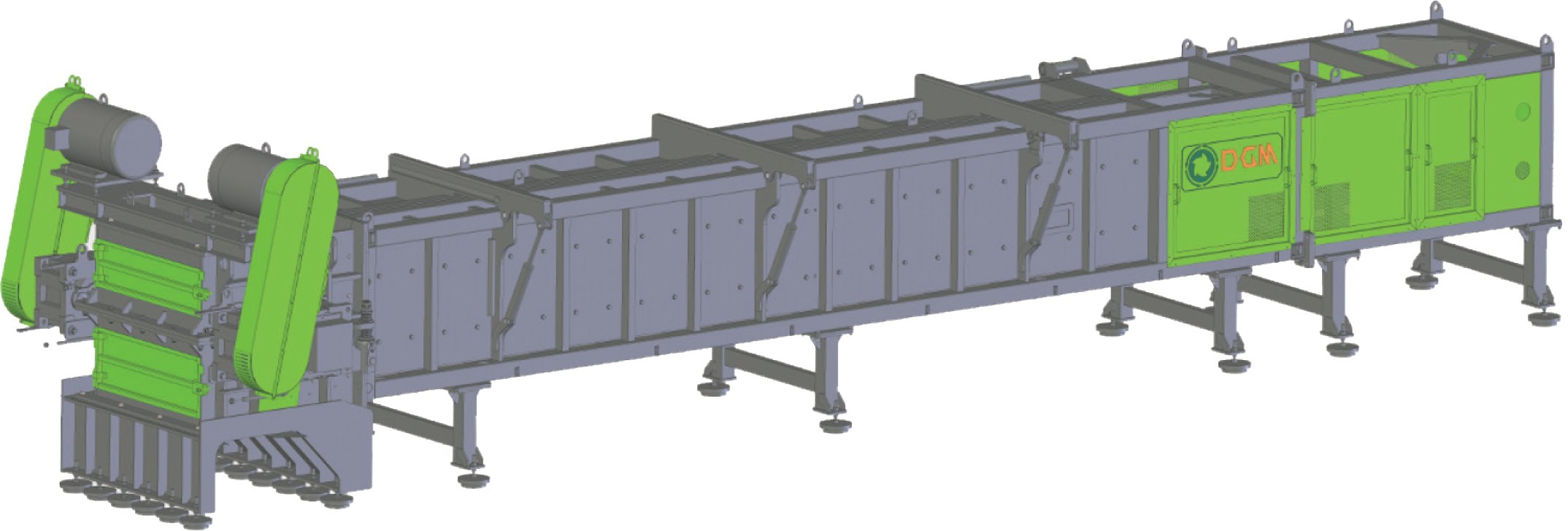

The hydraulically operated ram feeds the material horizontally in the rotor’s cutting chamber by load-related controls. The hydraulic system is equipped with high-pressure valves and volumetric flow controls which can be set according to the requirements of the input material.

Extremely robust pedestal bearing housings are mounted outside the machine and separate to the cutting chamber to prevent dust and dirt penetrating into the oversized bearings. This ensures a long service life and minimum service and maintenance.

Power is transmitted from the motor by a drive belt via an oversized gearbox which is located on the shaft end on one end of the rotor.

A safety switch prevents machine startup when the front panel is open and the machine features emergency stop buttons on the machine body and control panel.

APPLICATIONS

DGR Large Diameter Pipe Shredders have been designed with a wide range of applications and industries in mind such as:

PLASTICS / WOOD / PAPER

SPECIFICATION

MODEL | | 800 | 1000 | 1500 |

Cutting chamber | mm | 3870x700 | 6700x870 | 6700x1300 |

Rotor diameter | mm | 800 | 980 | 1430 |

Rotor speed | rpm | 40 | 36 | 23 |

Main motor power | kW | 2 x 37 | 2 x 45 | 2 x 55 |

Rotor knives | pcs | 60 | 108 | 204 |

Stator knives | rows | 3 | 4 | 5 |

Hydraulic ram power | kW | 11 | 15 | 15 |

Machine weight | kg | 11000 | 20000 | 25000 |

Effective working area | mm | 3500x630 | 6000x800 | 6000x1000 |

Dimensions | A | mm | 7700 | 11900 | 12200 |

B | mm | 1420 | 1540 | 1800 |

C | mm | 5060 | 8100 | 8100 |

D | mm | 38600 | 6700 | 6700 |

E | mm | 1730 | 1840 | 2320 |

F | mm | 2550 | 2970 | 3360 |

G | mm | 2570 | 2660 | 3150 |

H | mm | 975 | 1070 | 1070 |

I | mm | 590 | 590 | 590 |