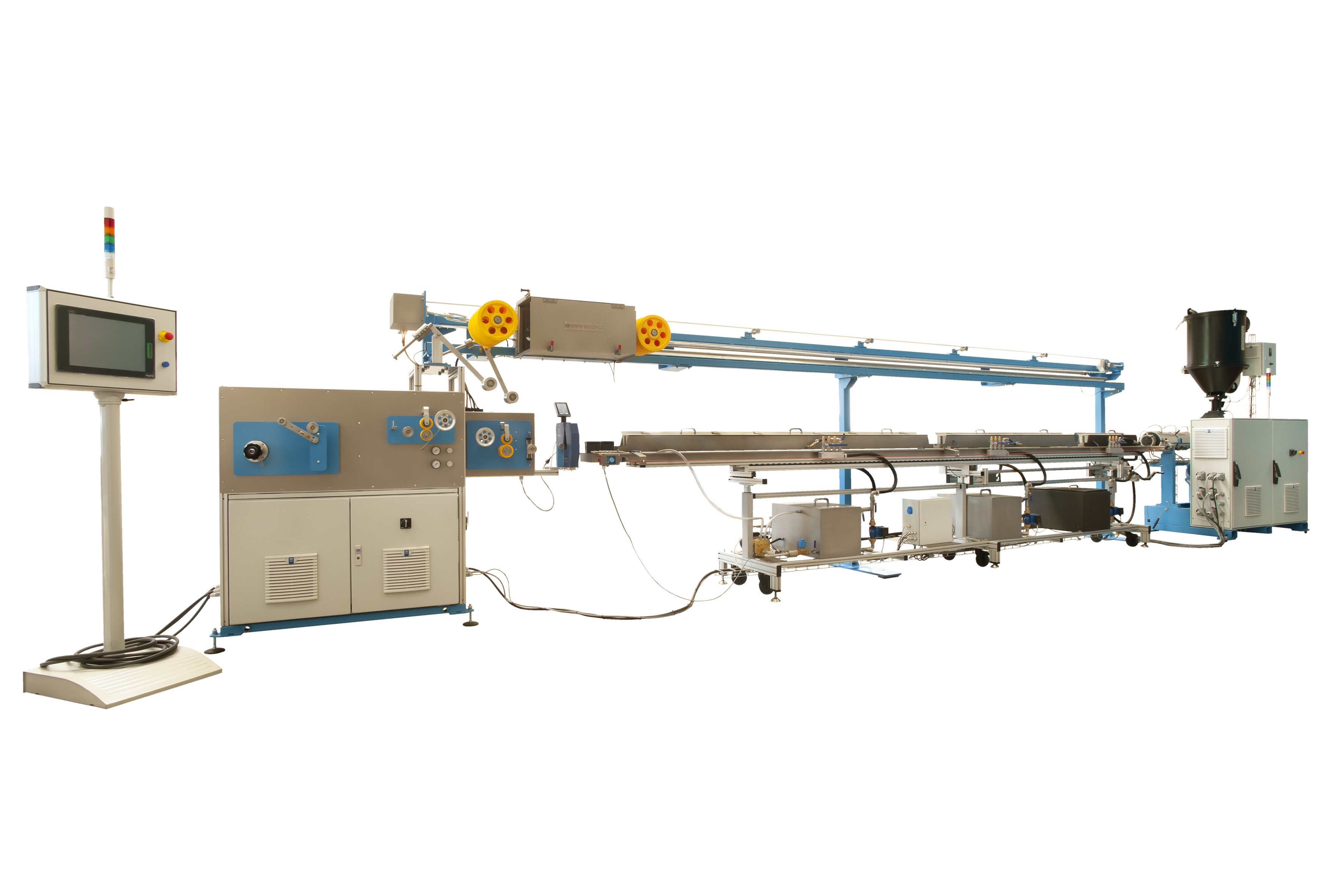

Our portfolio of extrusion lines also includes the extrusion line for production of filaments for 3D printers, welding wires, strings for garden equipment etc.

The line is designed for extrusion of materials ABS, PLA, PET-G, MARLEX, DOWLEX and for production of filaments of different diameters from 1.75 up to 5 mm.

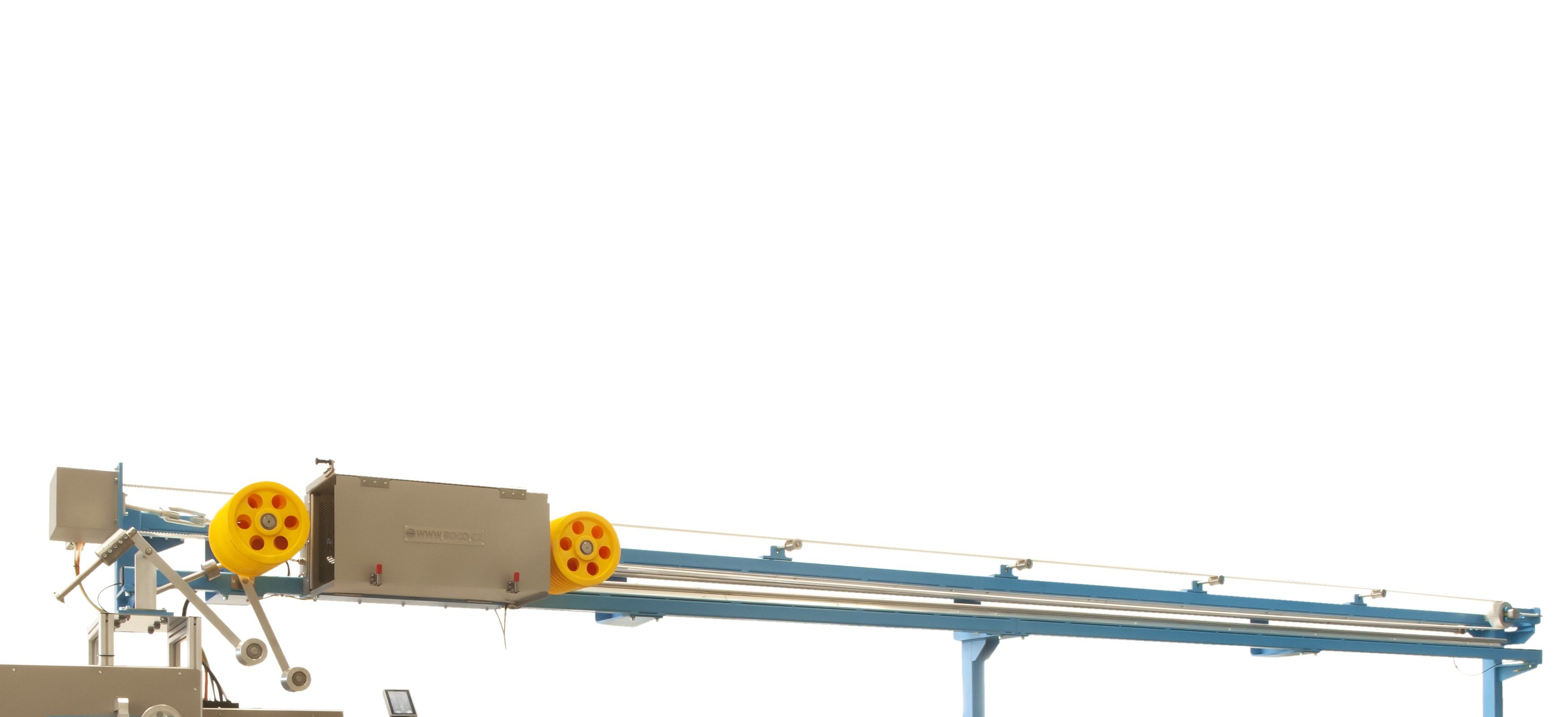

It is equipped with a compensator with a capacity of up to 140 meters, that allows the spool of 0.5 - 5 kg to be replaced without interruption of operation.

A 6-meter long cooling tank is devided into three sections. The first section allows water to be cooled or heated up to 80 °C, the second allows water to be cooled or heated up to the temperature of 50 °C and the third part is only cooled.

The line is controlled by a PLC panel with an automatic operation and is equipped with a triaxial measurement of a string profile, which automatically regulates the string diameter within the required tolerances.